We use our lab to remove variability from projects and startups. Anything we can physically mock-up and/or configure beforehand, we do. We then train our people + client teams to make the installation process go smoothly. Lower variability = lower risk = greater chance of success.

Although we cannot manufacture each and every situation that we’ll encounter in the field, by eliminating the pieces that we can, we are left with a smaller field of “unknowns” during startup. This process also allows us to spread training across multiple people at Process and Data Automation leaving no silos of information.

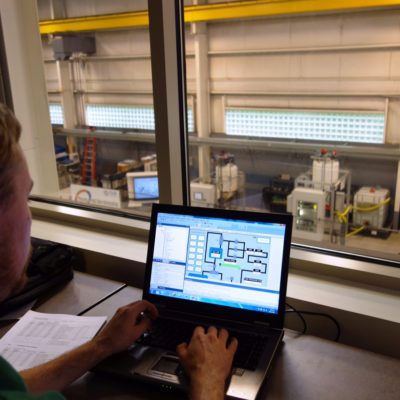

integrators can. The SCADA lab allows PDA (and our customers) to mock up any system and develop and test against it prior to implementation on-site. PDA has a variety of PLC’s, servers, and communications equipment on hand. Additionally, we have a variety of machinery in our industrial lab that allows PDA (and our customers) to test live our logic, data collection, and reporting prior to actual on-site project startup.

integrators can. The SCADA lab allows PDA (and our customers) to mock up any system and develop and test against it prior to implementation on-site. PDA has a variety of PLC’s, servers, and communications equipment on hand. Additionally, we have a variety of machinery in our industrial lab that allows PDA (and our customers) to test live our logic, data collection, and reporting prior to actual on-site project startup. Process and Data Automation (PDA) has created the Automation Excellence Series which offers exceptional training to customers on whatever and wherever they need it the most. The training (combined with other elements like Core Competency Coaching and the SCADA Lab) is a systems-based training at our Merwin Lane facility located at PSU’s Behrend Campus Knowledge Park but can also be brought onsite for the customer!

Process and Data Automation (PDA) has created the Automation Excellence Series which offers exceptional training to customers on whatever and wherever they need it the most. The training (combined with other elements like Core Competency Coaching and the SCADA Lab) is a systems-based training at our Merwin Lane facility located at PSU’s Behrend Campus Knowledge Park but can also be brought onsite for the customer! Process and Data Automation (PDA) developed the CORE Competency Coaching model for the purposes of offering hands-on application coaching. The lab environment created allows for a BYOE (Bring Your Own Equipment) – Controllers, HMIs, Instruments and more method.

Process and Data Automation (PDA) developed the CORE Competency Coaching model for the purposes of offering hands-on application coaching. The lab environment created allows for a BYOE (Bring Your Own Equipment) – Controllers, HMIs, Instruments and more method.