Process and Data Automation (PDA) reviewed and refined the scope of work required to upgrade failing controls equipment for one of the largest privately-held manufacturers of ice cream and frozen treats in the United States, at their production facilities in upstate New York. The clients needed the upgrades since the existing controls equipment was aged, unreliable and a DEP mandate for tighter controls and better reporting practices had been issued.

Process and Data Automation (PDA) reviewed and refined the scope of work required to upgrade failing controls equipment for one of the largest privately-held manufacturers of ice cream and frozen treats in the United States, at their production facilities in upstate New York. The clients needed the upgrades since the existing controls equipment was aged, unreliable and a DEP mandate for tighter controls and better reporting practices had been issued.

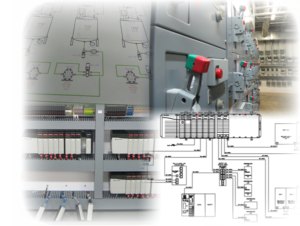

Completion of this project moved the facility from an unknown to a known state with respect to automation, as well as providing a comprehensive system overview contrasting the legacy, existing islands of discrete controls. PDA not only upgraded the core control equipment but also added Monitoring and Automated Reporting capabilities to replace the manual-entry method at the facility. PDA also delivered process narrative and documentation, that could easily be followed by the client, integrated disparate controls into a cohesive facility-based model and assisted the client’s ERP team with the integration of key data into the Oracle reporting system. The agile interactive approach to project planning allowed the client to achieve regulatory milestones in an expedited fashion. PDA also completed the upgrade of the core control hardware with selected use of existing equipment in order the minimize costs.

The major challenges to successfully completing the project included:

The solution implemented by PDA resulted in better visibility of the entire process, multiple adjustment points to fine-tune controls and the assurance that only approved materials are transferred. The facility now has automated chemical injection processes, separation of fat and valving and motors as necessary. Further, the tracking and data collection for the chemical dosing and for raw and corrected pH and TSS are available.

In the future, the client could consider increased capacity and different correction methods. In addition, the introduction of remote monitoring and increased data collection should be considered.

PDA is a full-service, CSIA Certified industrial control systems integration firm. Our Controls Engineering group specializes in physical automation system design, programming, and commissioning. We also feature a dedicated Digitalization Group (DSG) that connects automated equipment and systems to the business system environment including protected recipe systems, data collection and reporting, and data historian implementation. DSG can provide the systems you need to set your systems up for proper operation and then provide the tools you need to make sure you execute as planned.

Posted In: Application Stories, News

© 2024 Process and Data Automation, All Rights Reserved.