PDA is Krones’ North American Industrial IT Provider and KRONES.digital’s Execution Arm

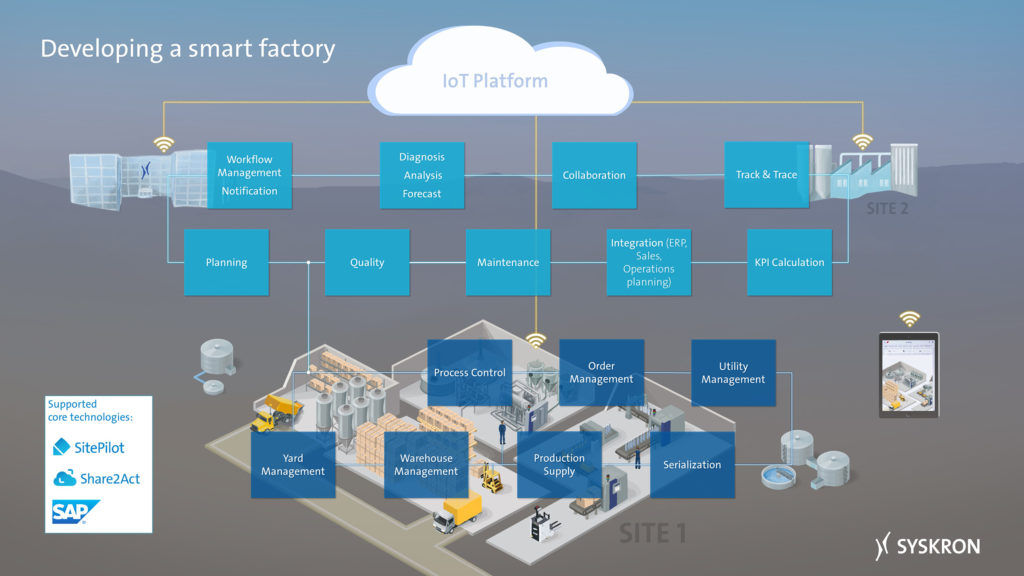

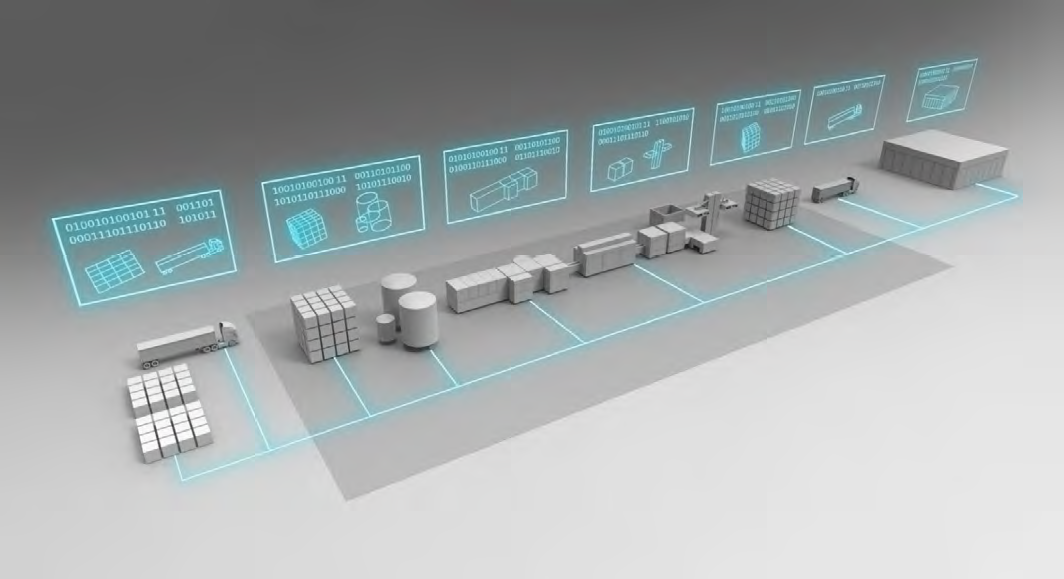

The KRONES.digital brand was created to bring all the IT products of the Krones Group together under a single roof. It has been developed into a holistic solution comprising Manufacturing Execution System (MES), Process Control System and innovative cloud solutions. The KRONES.digital software landscape is structured to form the complete supply chain of manufacturing from goods receipt to dispatch. KRONES.digital solutions can be used to plan, control, visualize, document and analyze processes along the complete supply chain.

KRONES.digital solutions are:

Benefits to you are:

The perfect tool for everyone who really wants to know exactly what is going on. This software gathers all the data relating to quality, costs and performance for individual machines or complete lines and summarizes the results in clear reports.

The perfect tool for everyone who really wants to know exactly what is going on. This software gathers all the data relating to quality, costs and performance for individual machines or complete lines and summarizes the results in clear reports.

This can be used for:

Benefits:

Controls the complete filling and packaging process, starting from the order-specific definition of the production route up to pallet labeling. This is because the modular SitePilot solution provides a continuous flow of information, from the production schedule to the order for the line and the individual machine. The high degree of automation enables equipment and materials to be used as efficiently as possible. The result: high-performance production with shorter changeover times, lower material consumption, and maximum availability.

Controls the complete filling and packaging process, starting from the order-specific definition of the production route up to pallet labeling. This is because the modular SitePilot solution provides a continuous flow of information, from the production schedule to the order for the line and the individual machine. The high degree of automation enables equipment and materials to be used as efficiently as possible. The result: high-performance production with shorter changeover times, lower material consumption, and maximum availability.

Benefits:

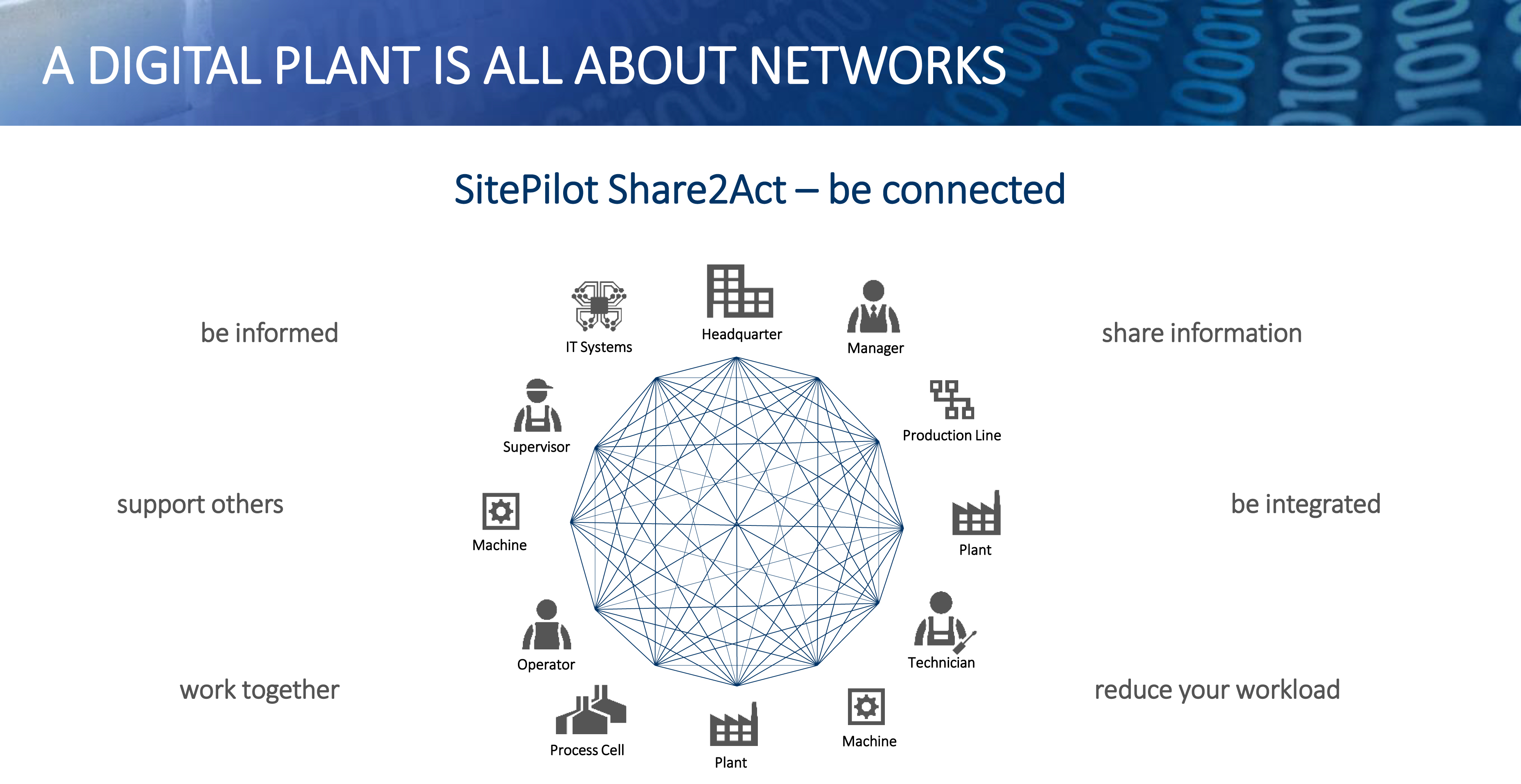

Shop Floor Guidance is a social media platform developed specifically for companies in the food and beverage industries. It networks all the people, machines and IT systems involved in the production process – and thus gets us a whole lot closer to our goal: you see, the app enables procedures to be streamlined, communication paths shortened, and downtimes reduced.

Shop Floor Guidance is a social media platform developed specifically for companies in the food and beverage industries. It networks all the people, machines and IT systems involved in the production process – and thus gets us a whole lot closer to our goal: you see, the app enables procedures to be streamlined, communication paths shortened, and downtimes reduced.

It groups together all a plant’s information on a central interactive platform. From automatically generated production data to empirical feedback from the staff, a huge array of different contents can be imaged, exchanged, discussed and jointly edited.

The essential idea of Shop Floor Guidance is to create a digital image of shop-floor reality. This already begins with the platform’s own structure: with the aid of hierarchically arranged production units, a company’s structure can be individually mapped.

In Shop Floor Guidance, each relevant production unit – the machine, then the line, all the way up to production departments – receives its own timeline, with a chronological listing of events. In addition, these individual timelines are grouped together to form higher-order timelines.

All Shop Floor Guidance users can (in the same way they’re used to on other social networks) author contributions, depending on the authorization involved. These posts can comprise text messages, images, videos or files.

For consistently harmonized IT interfacing of all process areas, a solution is now available in the shape of ReadyKit, which has been specifically designed for use in what is known as a brownfield environment. This enables older machines or models with a restricted communication interface or lacking one entirely to be integrated into the central data acquisition system. In addition, ReadyKit provides an option for computing key ratios and compensating for missing information with the aid of algorithms on the basis of measured and acquired values. These algorithms fall back on the acquired values over variable time periods.

For consistently harmonized IT interfacing of all process areas, a solution is now available in the shape of ReadyKit, which has been specifically designed for use in what is known as a brownfield environment. This enables older machines or models with a restricted communication interface or lacking one entirely to be integrated into the central data acquisition system. In addition, ReadyKit provides an option for computing key ratios and compensating for missing information with the aid of algorithms on the basis of measured and acquired values. These algorithms fall back on the acquired values over variable time periods.

Using ReadyKit does not require any elaborate retrofit work on the machine control systems, because the solution has been designed to use an enormous range of different data sources for acquiring the raw data. Firstly, there are interfaces with the machine’s control system, in order to acquire signals and values directly from it. Secondly, different sensors (e.g. vibration meters) can be linked up and read out, in order to acquire missing data with the aid of photo-cells, for example. The two options can also be combined for a comprehensive database.

Basically, this means that the most important information from the machines can be thus recorded and evaluated. Thanks to the minimized work involved in the installation, and the lean concept, clients can benefit very quickly and uncomplicatedly from ReadyKit, optimize their processes, and thus save costs.

What data is processed and generated?

Krones designs, develops, manufactures, and installs both machines and complete packaging lines. Krones has become one of the leading system suppliers for breweries and beverage producers as well as for the food, chemical, and cosmetics industries. Our 16,000 employees worldwide strive for innovation and detail and ensure that each customer receives the best quality in product and service. Learn more about them HERE.

© 2024 Process and Data Automation, All Rights Reserved.